Birring NDE Center – Eddy Current Training (ECT)

Eddy Current is common NDT technique used for inspection of heat exchanger tubing and surfaces. Eddy current training includes

Conventional Eddy Current – Tubing Inspection

Conventional eddy current is widely used for inspection of non-ferromagnetic tubing. These include stainless steel, Titanium, copper-nickel alloys, brass, etc. Inspection is done using a bobbin probe connected to a multi-frequency eddy current instrument. Eddy currency depends on the material resistivity (or conductivity) and thickness. Conventional eddy current has high reliability, high speed (upto 2 m/sec) and is used for inspection of nuclear plant steam generators, petrochemical and power plant heat exchangers and air conditioning chillers.

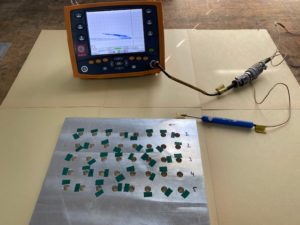

Surface Eddy Current

As the name suggests, this technique is used for surface inspections. The technique is highly sensitive, high speed and the inspection done using pencil type probes connected to a battery powered instrument. The technique can be used for non-magnetic and ferromagnetic materials. Applications include bolt hole inspection, turbine blades, turbine disks, bolts, etc. The technique is widely used in aerospace industry.

Bolt holes with EDM notches covered with tape for testing along with holes with no notches

Remote Field Eddy Current

Remote field eddy current is used for inspection of carbon steel tubing. This is low frequency test method and uses two coils in the transmit-receive mode. The normal frequency range for this test is 200 to 400 Hz and the inspection speed is slow. The method works well for detection of wall loss but is not suitable to detection of pitting and can miss pin holes.

Eddy Current for carbon steel weld inspection

This is a special application, normally offshore, where eddy current in used for carbon steel weld inspection. Typically these welds have a heavy paint coating and eddy current is used in lieu of magnetic particle inspections. This application uses special ECT weld probes that are lift-off insensitive. The inspection also requires specific technique and training.

Eddy Current for Clad Thickness

One special application of eddy current is clad thickness measurement. This is used to measure non-ferromagnetic clad on a ferromagnetic base, for example stainless clad on carbon steel. Inspection is done using large spot probes whose diameter > 2 x thickness and frequency is selected so that the depth of penetration is greater than the nominal clad thickness.